OUR FACTORY

Founded in 1976, our small artisan factory is located in the heart of Montegranaro, in the Marche region, a land renowned for the production of high-quality footwear. We work in a welcoming space, where tradition marries attention to every detail, keeping alive a long history of craftsmanship and creativity. Here, close to home, we produce footwear that embodies the true spirit of the Marche region and the passion for our craft.

Our Artisans

Our artisans are the beating heart of our business. True masters of the industry, they put their passion and dedication into every single phase of production. Every shoe we make is the fruit of expert hands that take care of every detail with attention, precision and love for craftsmanship. It is thanks to them that we are able to create unique products, capable of telling a story of excellence and tradition.

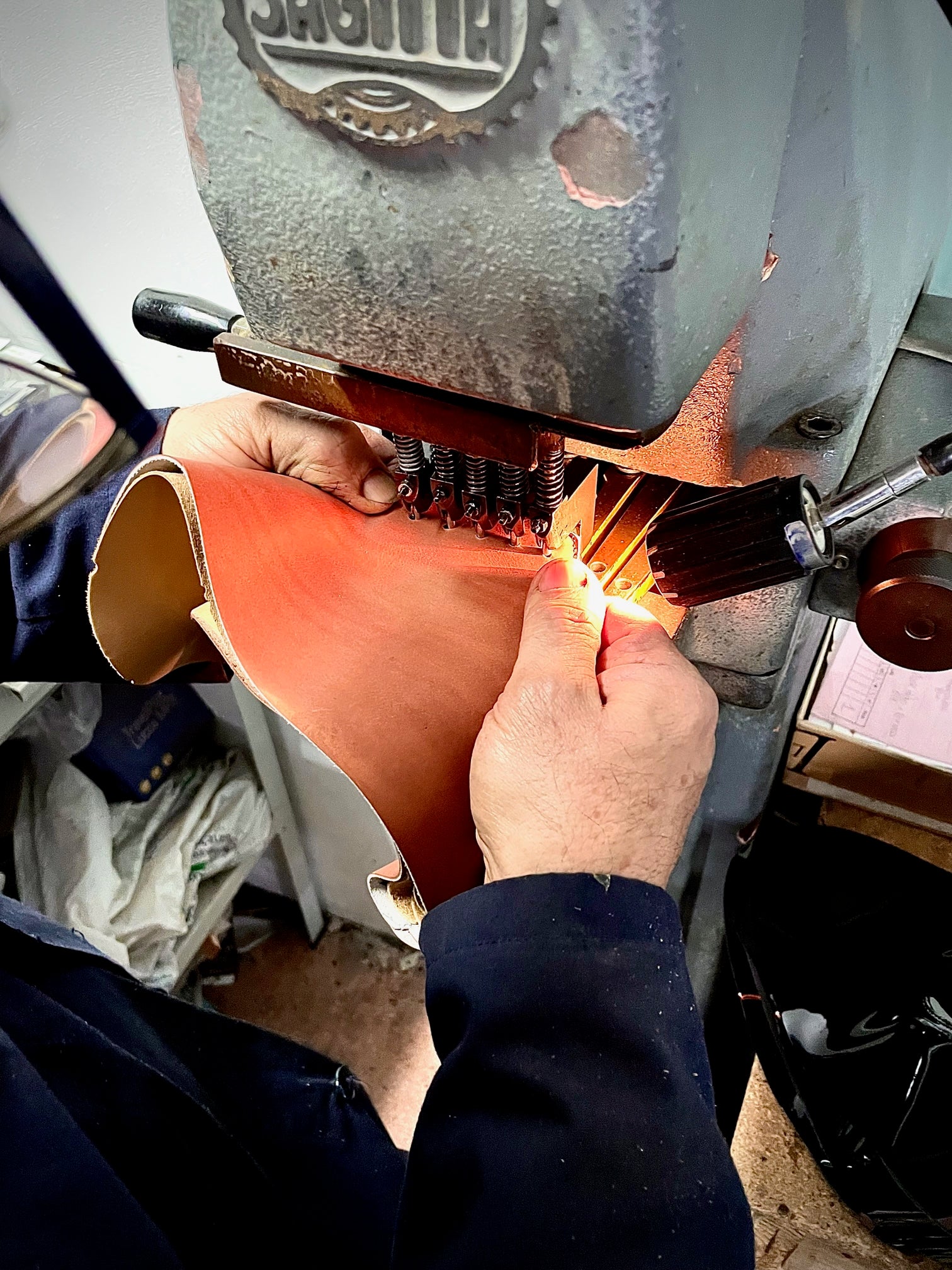

The Machinery

We use very little machinery in our production, because we believe that the human touch makes the difference. Each phase of the process is followed manually by our craftsmen, who carefully check every detail to ensure an impeccable final product. This choice allows us to maintain a sustainable and environmentally friendly production, limiting the use of mechanical resources to a minimum.

Artisanal Processing

Our story comes to life in over 100 intricate stages, a harmonious ballet performed by specialized craftsmen. Each pair of shoes is the result of extraordinary know-how and rigorous quality control that permeates every phase of the production process. Master shoemakers and Lancio stylists work together synergistically to create shoes that embody personality, elegance and uncompromising comfort, from morning to night.

With deep experience and knowledge acquired from the finest shoemaking techniques, we expertly blend tradition and innovation. Every day, we strive to perfect even the most complex constructions, such as Ideal, Goodyear, slip, Blake Rapid, ensuring that each shoe reflects our unparalleled commitment to Italian excellence.

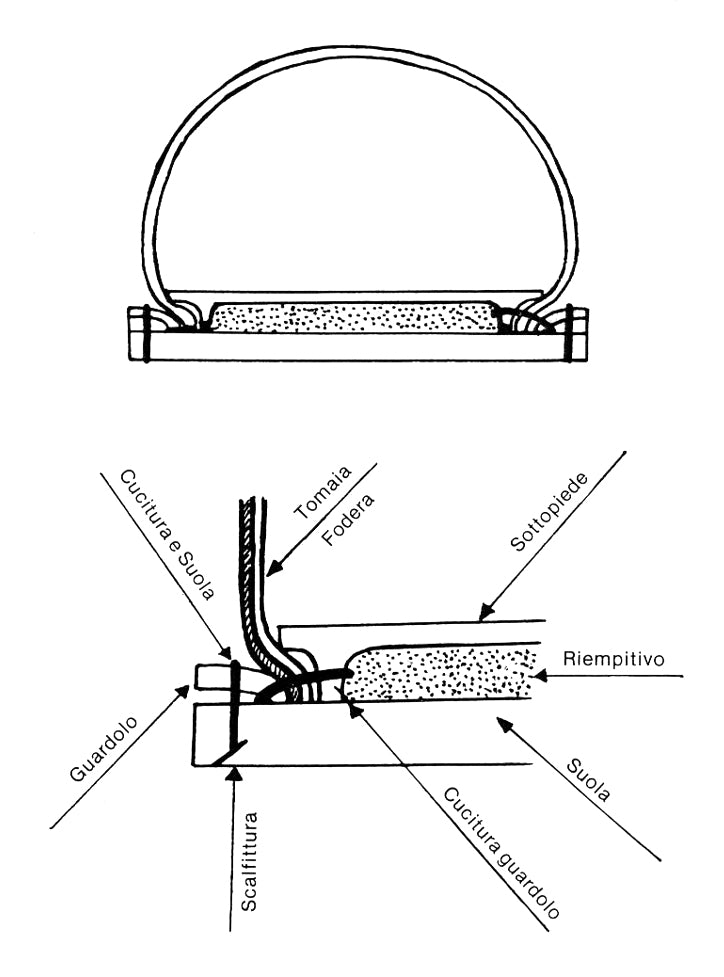

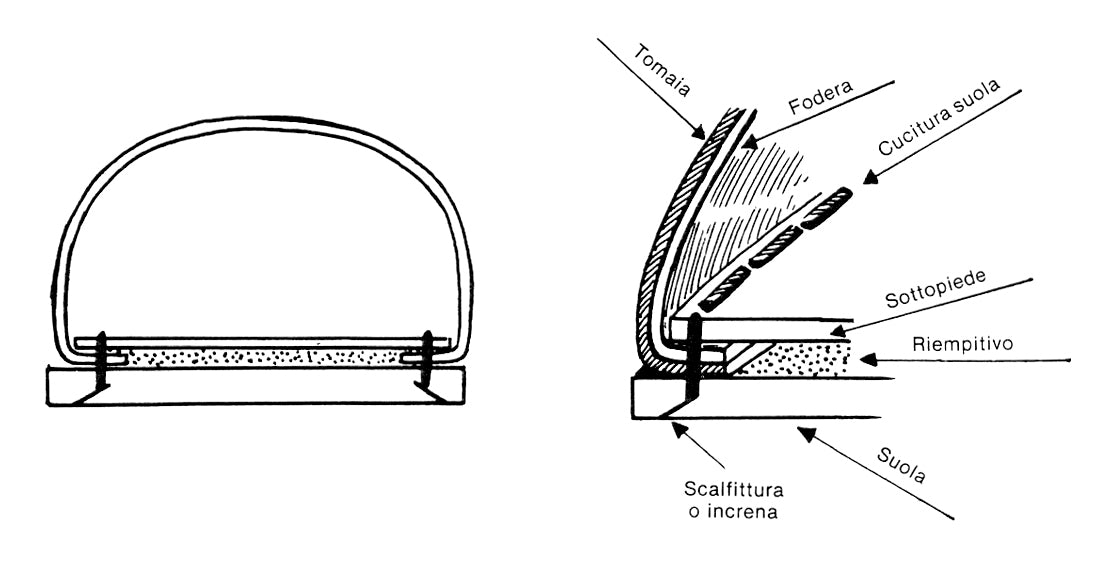

GOOD YEAR

It is an ancient process and bears the name of the inventor Charles Goodyear (1832): the process consists of two seams, the first joins the insole to the upper and the welt, the second joins the welt to the sole.

The insole is normally reinforced with fabric.

The “Goodyear” stitching is a very slow process that requires great manual skill, which is why it is considered the most esteemed workmanship. In this system, the various parts are not perforated and the grandeur of the work consists precisely in the section of the stitching carried out meticulously by the craftsman. In this case the stitching is not visible on the inside.

This process defines a resistant but at the same time soft and flexible shoe.

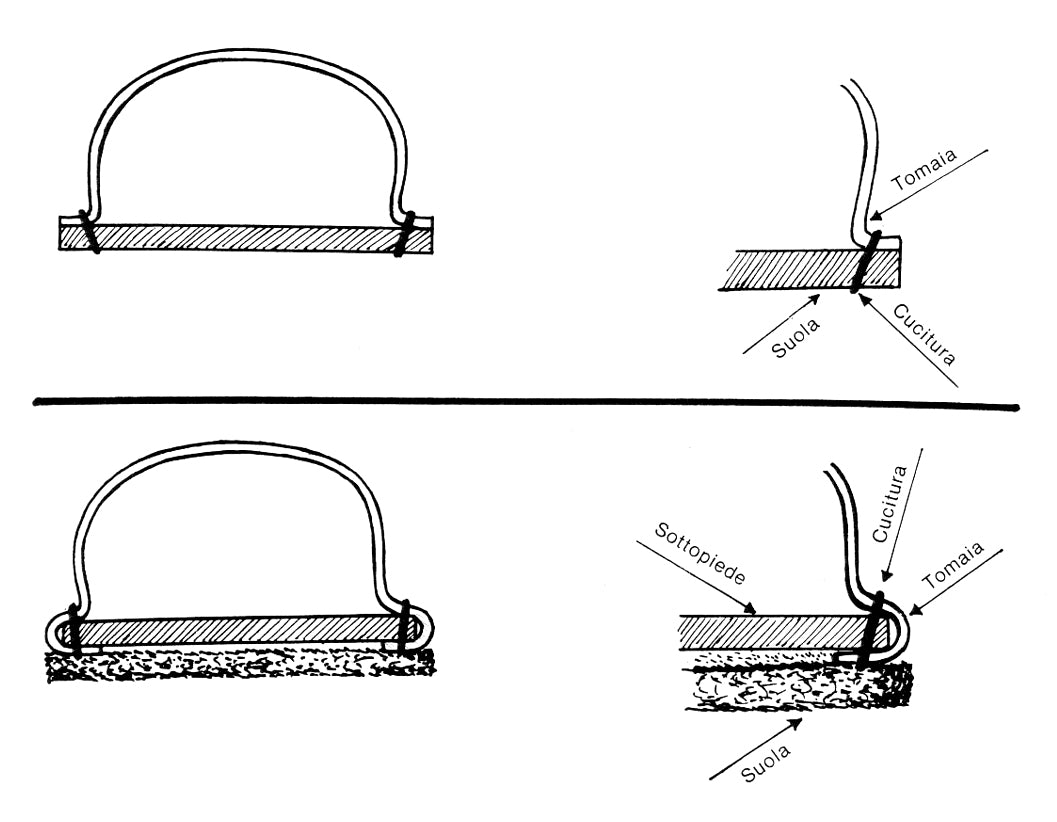

IDEAL

The upper is prepared with the external edges glued and pressed onto a special midsole and then sewn; cotton thread is first passed through a specific boiler, where there is melted pitch, to ensure the total impermeability of the thread and the holes.

This system has a much simpler variant which consists of turning the edges of the upper outwards and mounting them directly on the sole.

Particularly suitable for summer footwear such as sandals. It gives the shoe lightness and flexibility. It is possible to apply variants, which allow for a thick and winter sole (for example rubber).

BLAKE

The Black process is named after the inventor of the machine that sews inside and out. To sew the sole, the last must be removed and re-threaded for the finishing operations. This stitching is visible on the insole.

This type of processing makes the shoe flexible and resistant.

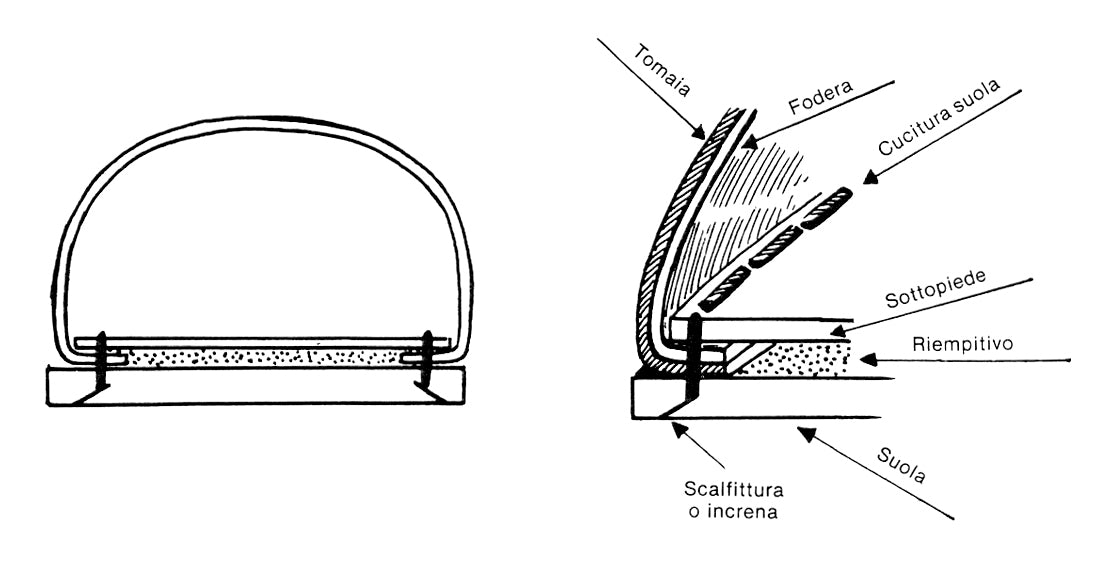

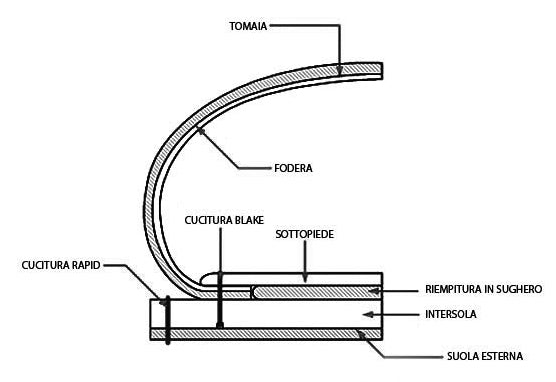

BLAKE RAPID

The Blake-Rapid construction is a combination of the Goodyear and Blake methods, it is one of the oldest and most prestigious construction techniques, characterized by two stages: the first internal stitching (Blake) joins the upper, insole, lining and midsole. The second external stitching (Rapid) binds the midsole to a further layer of leather, which constitutes the final bottom of the shoe.

Advantages: The Blake Rapid construction allows the shoe to be resoled, it is often used in winter footwear, it makes the shoe comfortable, waterproof, comfortable to wear and very durable over time.

BAG

Not all models are suitable for this type of workmanship, but for some (such as house slippers, simple summer footwear) it is particularly suitable. The upper is sewn to the insole together with the band that then covers the wedge. For this workmanship the upper is not mounted with “pliers” on the form but simply threaded. Therefore if the model is not perfect the defects can only be eliminated with heat.

Advantages: the bag manufacturing guarantees maximum softness, lightness and comfort.